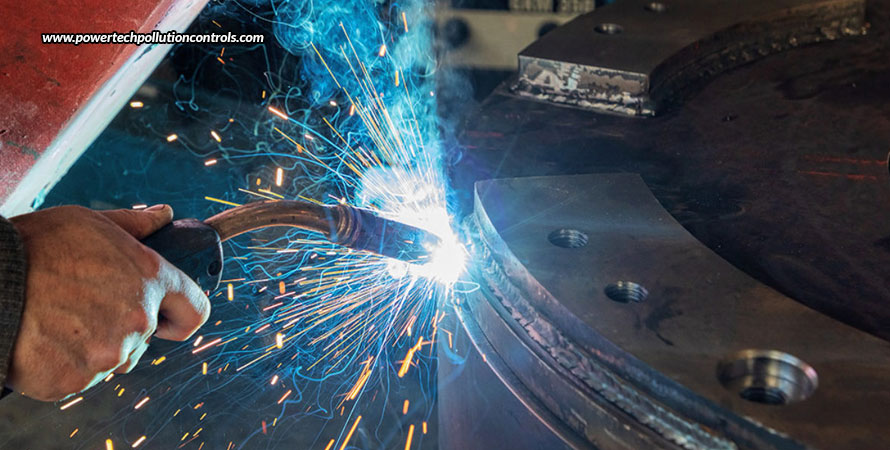

Welding Fumes – Why They Need To Be Removed

When metals are welded together, toxic fumes and gases are generated, and released into the airstream. The particulates in such fumes are typically smaller than even 0.1 µm, which means not even a 99th part of a strand of the hair! With an average strand of hair being only 99 µm, you can imagine how the particles in welding fume are so tiny that they can never been seen to the naked eye. Now, if the size is so small, its certain that the concentration will be greater. Imagine the amount of danger such high concentrations of particulates may cause!

How can particulate matter prove to be dangerous?

The particulate matter found in welding fumes can include harmful metals and gases like carbon monoxide, carbon dioxide, nitrogen, argon, and hydrogen fluoride. These gases get easily trapped in the respiratory system, targeting the bloodstream, central nervous system, and kidneys. Also, the fumes can settle on fixtures, causing equipment malfunction issues, and on the floors, increasing the risks of falls and slips. All in all, if these contaminants aren’t controlled and captured, there is an increased risk of health and safety injuries. This is why it is absolutely essential to collect the fumes at or near the source, using a fume extraction system.

What is a fume extraction system?

Welding fume extraction systems are useful to capture harmful fumes, gases, smoke, and other airborne contaminants, before reaching the breathing zone. These systems are designed to extract, filter, and clean contaminated air, and then return it back into the premises as clean air, or exhaust it outside altogether. For instance, the Fumekiller from Powertech Pollution Controls is a high-efficiency two-stage electrostatic precipitator, that is designed and developed for the capture and control of fumes, mist, smoke, and fine dust; thus proving to be a diverse welding fume extractor India.

Safe work practices that must be ensured

Employers must remain proactive in maintaining safe working conditions wherever welding procedures take place. Welding safety measures must be regulated, and employees must be trained about the importance of proper fume control, in order to ensure their safety. Good and appropriate ventilation is certainly a must to supply fresh air to your environment, but that alone cannot be relied upon, where harmful processes like welding is executed. This is why a fume extraction system is required. Moreover, these systems must be properly used and positioned, based on the specific machining process and application taking place, to guarantee effectiveness.

Negligent work practices can result in overexposure to air contaminants, thus increasing health risks and putting your people at danger. Apart from installing fume extraction system, let’s also help you understand a few other easy ways to improve the safety in your welding environment.

- The work area must be properly ventilated.

- Every welder must be equipped with personal protection equipment and gear to keep their eyes, face, and skin protected.

- Evaluate work practices to ensure that your employees are performing welding processes as safely and efficiently as possible.

- You must conduct hazard inspections regularly to ensure that the work environment meets every required regulation.

- Check for any required updates, new equipment, and changes to current processes that can bring about improved safety measures.

- There must always be a 35-foot clearance around the welding area, to ensure safety in the worst scenario of a fire hazard, wherein the welding project can be relocated to a different area.

As an employer, make sure you have all this in check, so as to keep your workspace and your employees free from danger.