10 Facts About An Extraction Arm For Effective Fume Extraction

When it comes to point extraction during welding operations, an extraction arm is an essential choice. And this is precisely what is advised for efficient welding fume extraction. Point extraction prevents welding fumes from escaping into the hallway by capturing them where they occur, right at the source. With an extraction arm, however, everything depends on the right properties. Extraction arms have fundamentally distinct qualities in several ways. The following list comprises ten facts regarding an extraction arm for effective welding fume extraction.

- In industrial environments, an extraction arm is a crucial instrument for efficient fume extraction. It has been designed to capture and remove dangerous gases, fumes, and particles produced by a variety of activities.

- In processes like welding, soldering, painting, chemical reactions, and other activities where dangerous vapours are produced, extraction arms are frequently utilized to contribute to worker health protection by eliminating airborne contaminants.

- A safe and healthy workplace is maintained in large part by extraction arms. They assist in lowering the risk of respiratory disorders, eye irritation, and other health issues linked to exposure to toxic substances by efficiently eliminating hazardous vapours, gases, and particulates.

- Depending on the exact application requirements and the distance from the source of the fumes to the exhaust system, the length of the extraction arms might range from a few feet to several metres.

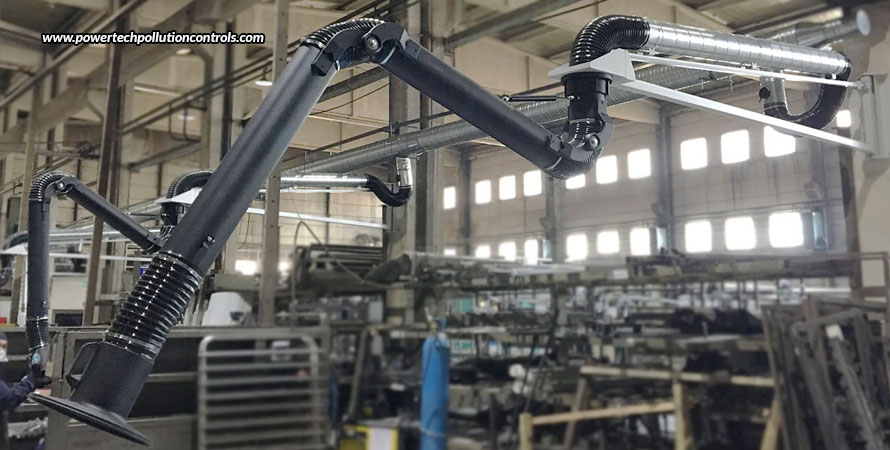

- Extraction arms consist of a flexible or telescopic hose that is attached to a source-capturing hood or nozzle. The flexible design ensures effective capture of pollutants at their source while enabling simple manoeuvrability and precise positioning.

- Many extraction arms have an articulating joint or a swivel base, giving them more flexibility, and enabling users to change the arm’s direction and angle to capture fumes as effectively as possible.

- Some extraction arms have added features to improve their use and functionality. These might consist of built-in illumination near the hood to improve visibility, filter monitoring systems to notify users when filters need to be changed, and automatic start/stop features that turn on the extraction system while the arm is in use.

- The airflow capability of an extraction arm determines its efficacy. It is essential to pick an arm with enough airflow to efficiently capture and convey the pollutants. The airflow capacity is influenced by things like the hood’s size, the hose’s diameter, and the extraction system’s power.

- For optimal fume extraction, the extraction arm must be positioned correctly. To ensure that the contaminants are caught before they spread into the surrounding environment, it should be placed as close to the fume source as is practical. The height and angle of the arm can be altered to enhance its efficacy.

- Regular cleaning and maintenance are required to keep an extraction arm operating at peak efficiency. Inspecting and cleaning the hood, clearing the hose of any obstructions or debris, and checking the joints and swivel mechanisms all fall under this category.

To conclude, extraction arms are useful equipment for efficient fume extraction. They are able to effectively catch dangerous contaminants at the point of origin, thanks to their adaptable design, customizable location, and airflow capacity. Businesses can prioritize employee health and safety, enhance interior air quality, and adhere to legal requirements by employing extraction arms properly. If you’re concerned about the health of your people too, you may always get in touch with Powertech Pollution Controls to get your hands on the finest extraction arm, which you can use in connection with the Fumekiller, the finest welding fume extractor India, manufactured to capture and control fumes, mist, smoke, and fine dust, by combining a high-efficiency two-stage electrostatic precipitator with electrostatic filtration technology.